Reproducation and Improvement of Vision-based Tactile Sensors

Published:

I reproduce and improve the design of GelSight-like tactile sensors, including GelSight and DIGIT.

0. Preparation of Hardware Materials

| Type | Item |

|---|---|

| General equipment | Voltage-stabilized source; Air brush; Oven; Electric soldering iron |

| Materials for GelSight | TPU; TPU coating glue; Metallic paint; Tin powder (high purity); Acrylic board (3cmx3cm); LED lamp belt (red, green, blue, white); Fisheye camera; Shell (3D printed) |

| Materials for DIGIT | Fully transparent silicone; White silicone ink; Silicone glue; Acrylic board (6mm); Shell (3D printed); Marker paper (water printed) |

1. GelSight

1.1 Fisheye camera calibration

Using a 7 * 7 chessboard grid (with a single edge length of 6mm), the original image and the distorted image are as follows:

The calibration method refers to gelsight

1.2 Reflection membrane production

For gel elsotmer, the 7cm * 7cm shockproof pad (made of TPU) sold online is used. According to the actual demand, it needs to be cut to about 2.5cm * 2.5cm.

For the production of reflection membrane, a relatively good process has been found as follows:

- Cover one side of the silicone with tin powder (because the silicone itself is sticky, simply put the silicone in the tin powder; also, the tin powder must be relatively fine and not have a grainy texture);

- Spray with metallic paint (be careful not to apply too much);

- After the paint is roughly dried, cover the surface with TPU coating glue (which can protect the reflection membrane and improve its durability);

- Continue drying.

Attention! Protect the edges and sides of TPU throughout the entire process

1.3 Finished product display

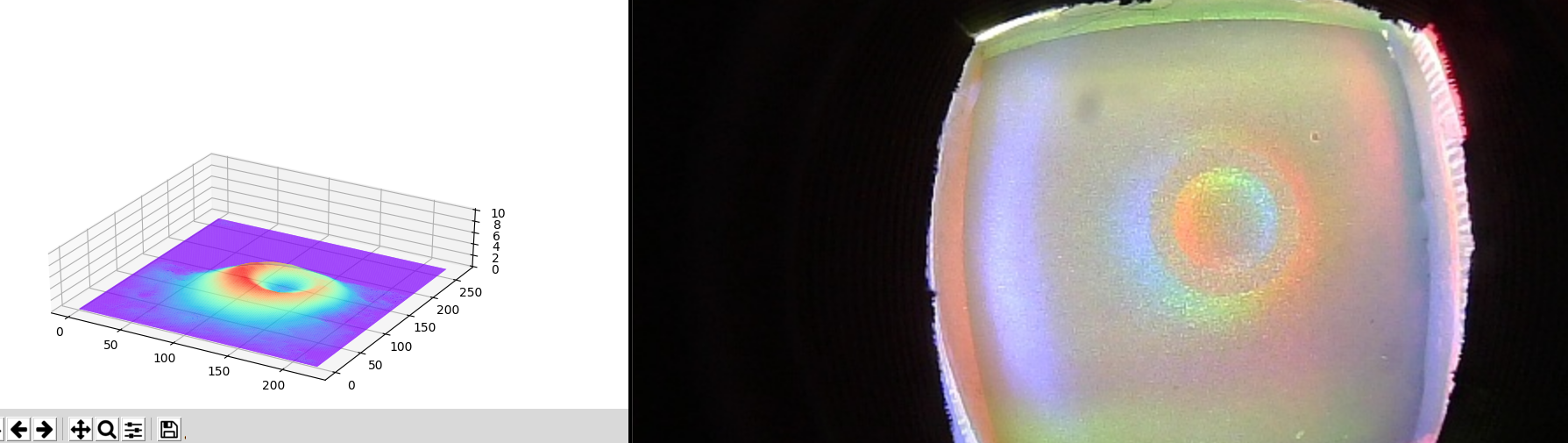

- Depth reconstruction

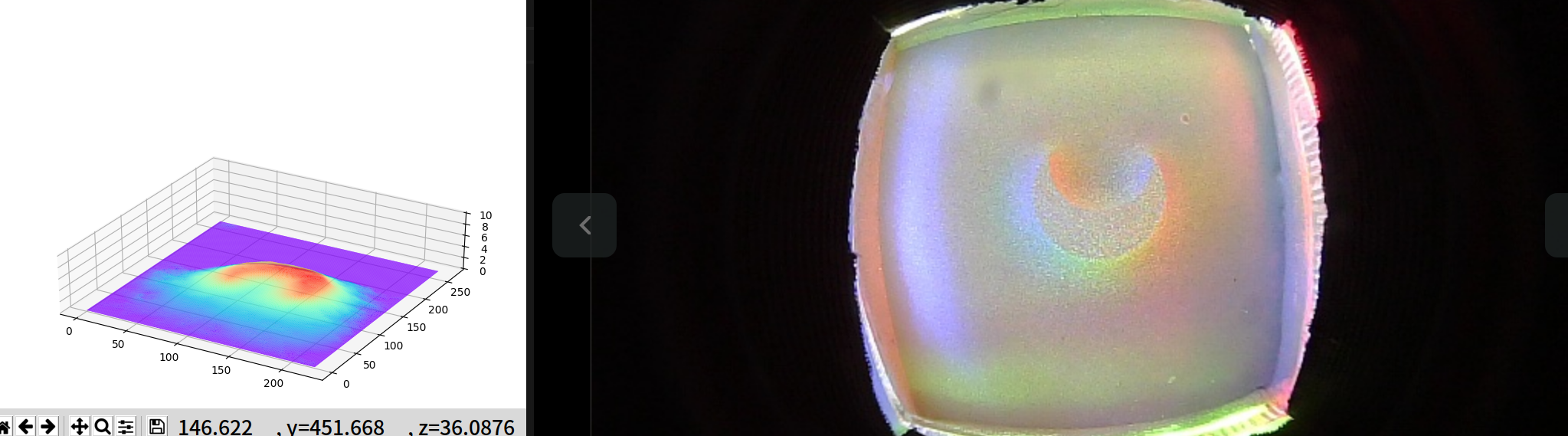

- Equipped to robot arm

2. DIGIT

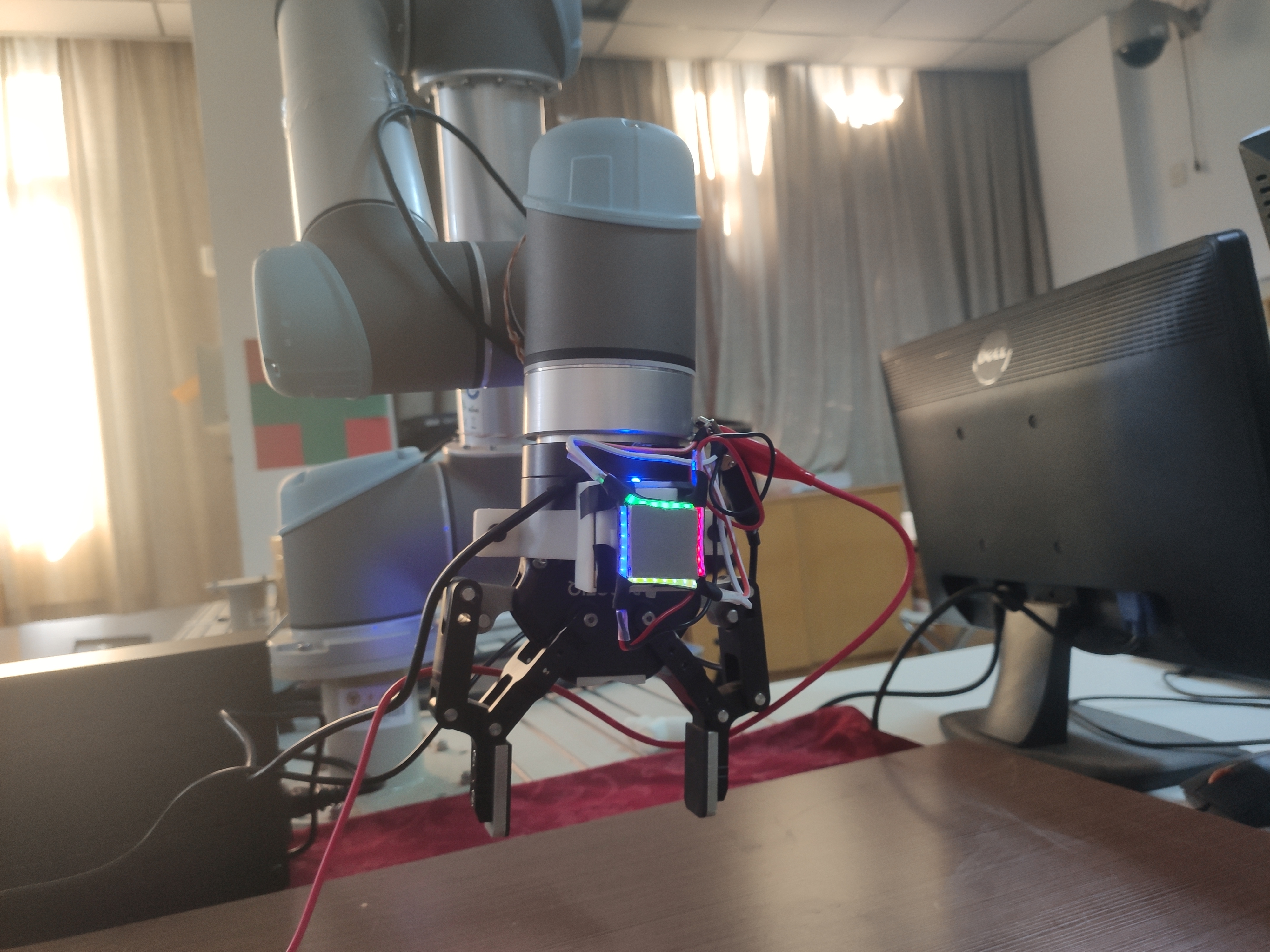

2.1 Production of gel elastomer and reflection membrane

- 3D printed the gel mold of DIGIT, using food grade fully transparent liquid silicone with a shore hardness of 5 degrees, mixed with silicone A & B adhesive in a 1:1 ratio, heated in an oven at 90 ° C for 10 minutes;

- Dilute the hand feeling oil (hand feeling oil: curing agent: diluent=100:3:400) and evenly spray it on the surface of silicone to create a matte effect. First, let it stand at room temperature for 5-10 minutes, then heat it in an oven at 180-200 ° C for 15-20 minutes;

- Dilute white silicone ink (ink: curing agent: diluent=100:3:500) and spray evenly on the surface of the hand felt oil using a air brush;

- Use 6mm thick transparent acrylic board as the support of gel elastomer;

- Use silicone glue to bond the acrylic board with the gel.

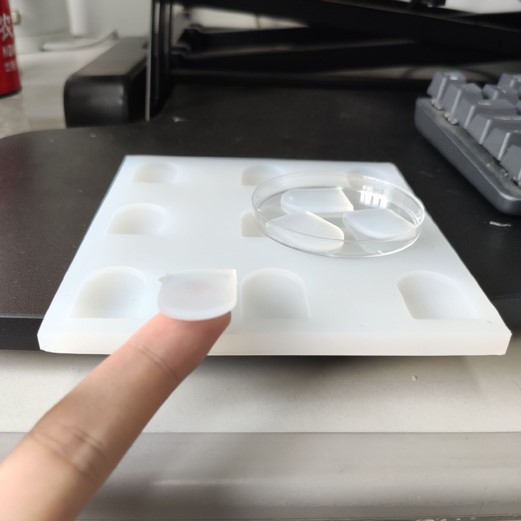

2.2 Production of markers

Using watermark techniques (similar to water soaked tattoo stickers)

The pattern of the marker is shown in the following figure:

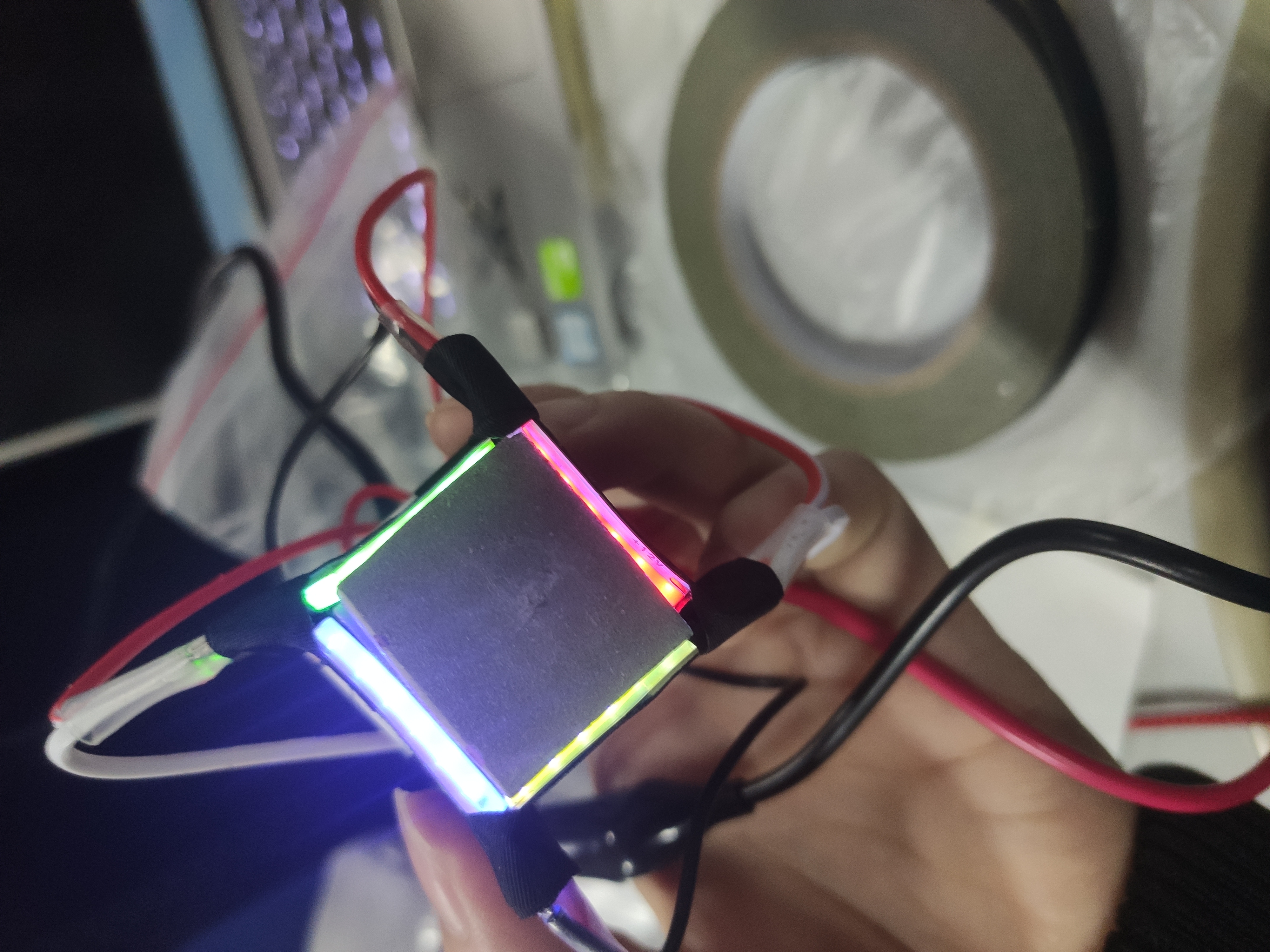

2.3 Finished product display